Prism Fluid Bed Processing involves Pallets and Granules coating and drying of particulate materials. It is ideal for heat sensitive and non heat sensitive products in Pharmaceuticals, Biotech, Nutraceuticals, Cosmetic, Chemicals, Biochemical, Food, Dairy, Confectionery, Agrochemical, Herbals, Ceramics, Detergents and Pharmaceuticals Institutes.

The equipment is use application for following process.

- Aqueous or Solvent based solutions or suspensions

- Enteric Release coatings

- Controlled release coatings.

- Fine particle coatings

- Active layering.

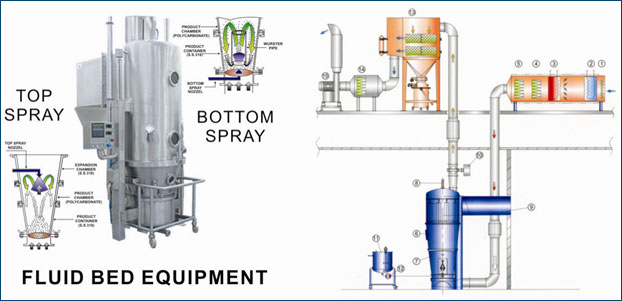

Depending on the application required Prism fluid bed Equipment can be configured into designs as follows.

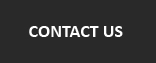

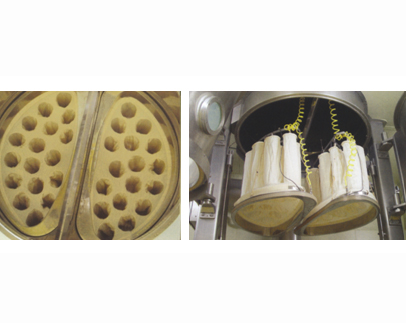

Fluid Bed Equipment with Wurster Coater Bottom Spray for Granules Coating or Pellet Coating :

This process is used to apply a coating to the granules or pellets. This process knows as wurster coater. In this process the spray is done inside a hollow cylinder and from the bottom of this cylinder the pellets are allowed in small quantity to enter the hollow cylindrical tube. Than the particles are passing the bottom spray guns in orderly manner quickly moving upward the tubes to avoid agglomeration. Once they are outside the wurster compartment, they move downward outside the compartment where they dry another layer of coating can be supplied. Since the movement of the particle or pellets inside the wurster chamber totally controlled in ensures uniform. |